Frequently Asked Questions

Ordering and Payment FAQ'S

We are located at :

525 Pitts School Rd NW

Suite A

Concord, NC 28027

Our Hours are

Monday - Friday

10am - 5pm

No fee for paying with Cash or Check

Credit Card Payments are accepted.

VISA - MASTERCARD - AMERICAN EXPRESS

Credit card payments are charged a 4% fee

Once payment has been made you can head over to the Order History page to check the status of your purchased orders. Once your order has switched to "In Production" you will no longer be able to make any changes or cancel your order.

General FAQ's

We use bank level encryption on every page and for every transaction that is placed on the site. This is more than is necessary for an online store like ours, but it speaks to our commitment to keeping your information safe. Always look for the lock.

No information we collect for order processing or from inquiries is shared with any other company or website. Your information is only used to contact you when necessary. Credit Card information is only used to bill you for products and services ordered.

Our secure shopping cart uses the latest secure server technology. Your order is submitted and retrieved with a secure connection to our server and remains secure at all times.

Most experts consider that ordering securely on the internet is as safe or safer than giving your information over the phone or to stores. Most cards have a Zero Liability policy for internet use and limit your liability in the case of fraudulent use of your card.

No, proofs are only for clients that have financially committed to a project with us.

UV printing is a form of digital printing that uses ultra-violet lights to dry or cure ink as it is printed. As the printer distributes ink on the surface of a material (called a "substrate"), specially designed UV lights follow close behind, curing - or drying - the ink instantly. Basically we bake the ink onto the surface.

Originally developed for quickly drying gel nail polishes during manicures, ultraviolet light applications quickly expanded into industrial and commercial markets. Because the UV lights cure any printed ink immediately, the dots of wet ink do not get a chance to spread out once printed, resulting in much finer detail. In addition, UV cured inks are weather-resistant and offer increased resistance to fading. This curing process is more environmentally friendly as it produces few VOC’s, odor, and heat. UV curing also allows the flatbed printer to be used with nontraditional materials like acrylic or aluminum. In fact, this UV flatbed printer is compatible with most substrates up to 2” thick!

Unfortunately, we are not able to offer refunds on any printed orders unless there is a problem with the print itself. We send proofs for you to confirm before we start printing to lower the possibility of errors.

It has always been our motto that, "If it doesn't look good, don't send it out to our clients." If your print or experience isn't to your satisfaction, let us know and we will reprint your order or fully credit your account.

When you place an online order, you will have the option to receive a PDF proof via email or via our proofing software or have your order go straight into production after we receive payment. If you select the proof option, you will be emailed a proof that you must approve via email or a link that will take you to our proofing software for you to make changes or approve prior to your order going in to production. The proof contains an image of your banner, billing and shipping information and payment information. You will not be charged until you approve your proof. Our customer service hours are 10:00 am - 5:00 pm EST.

The main inks we use for printing are UV inks and Eco-Solvent inks.

In printing terms, a proof is a digital copy of what the artwork file should look like when printed. It is your last and best opportunity to make sure the print job comes out the way you want. By carefully inspecting the proof, you can help us assure an accurate, flawless delivery of your print job on the first run. When an artwork proof is selected we check to make sure the artwork file is set up properly for print which includes adding hemming, grommet marks, and cut contour lines (if needed/selected). We are NOT responsible for checking over the quality, information, spelling, grammar, etc. We do recommend if you are concerned with quality to be sure and zoom into the graphics so that way you will also see the banner graphic up close as if it were printed. Very often, a designer will retype information they’ve been supplied when creating a proof. That’s why you need to check every element of the design to make sure it’s correct.

Key areas to check:

- Spelling, grammar and punctuation

- Contact details (phone numbers, names, email addresses, dates, times)

- Pictures and logos (are they sharp enough?)

- Graphic components and images (are all of my images included?)

- Layout (is the information in the correct spot?)

*Note: Colors in your proof may slightly vary from screen to print. (see why)

Our Services

We have one core logo package that includes:

- 3 Initial logo designs

- 1 set of revisions

- PLUS you recieve the finalized logo files (.AI, .EPS, .PDF, .PNG, and .JPEG)

Build your OWN package

Use ADD ONS to build you own logo package.

- Have us create a Brand Style Guide

- Trademark your design

- Have us come up with a character or mascot

- Additional Designs

- Extra Revisions

- Letterheads Design

- Email Signature Design

- Business Card Design

- Logo Refinish

- Update your Logo

Digital Die-cutting is a service we provide at Two Minds Group that works without the use of a metal-cast die to create anything from packaging, signage, invitations, envelopes, trade show exhibits, vinyl cut letters and more. Unlike traditional die cutting, our digital die cutting services provide enormous flexibility, flawless cutting technology, low production costs, and a large variety of substrate choices. Whether you’re interested in die cut on demand, die cut singles, or thousands, digital die cutting allows you to express your most creative concepts in an individualized, yet cost-effective, manner.

Design FAQ's

A cut contour line is a digital line added to a vector image prepared in a vector graphics program like Adobe Illustrator that tells the cutting machine where to cut. The line is not printed it is only used to cut.

Also may be referred to as "digital die-cut"

Typically the cut contour line is automatically set as the artboard perimeter. For square-cut projects make the artboard the finished sized. For projects the have a cloud cut or die-cut: create an outline representing how you would like it cut. Add a 0.25pt stroke with the color at 100% magenta. Place this on a new layer titled "Cut Contour" and place it on the top layer of your artboard.

Click here to learn what types of cut contour options we offer.

All images should be 300 dpi. DPI is the amount of ink dots per inch; 300 dots per inch is the required standard for printed material. Anything below 200 dpi may not be good enough resolution for printing.

Yes we print borders, but they are not recommended on double-sided prints. Because our substrates sizes vary from batch to batch it makes exact cuts difficult. We will NOT reprint or credit any order that has irregular borders on double sided prints.

What is Bleed?

Ink that prints beyond the trim edge of the page to ensure it extends to the edge of the page after trimming. As there is a degree of movement when printing on any press, you should always create 3mm bleed on all edges where bleed is needed. Supplying your job without bleed may result in white lines when we trim it.

We LOVE PDF's! But we also accept other formats as well.

- EPS - Encapsulated Post Script

- AI - Adobe Illustrator

- PDF - Adobe PDF

- SVG - Scalable Vector Graphic

- PSD - Adobe Photoshop

- JPG - High Resolution JPEG

- TIFF - High Resolution TIFF

Any of these files can be uploaded to our super dooper artwork upload tool.

In printing terms, a proof is a digital copy of what the artwork file should look like when printed. It is your last and best opportunity to make sure the print job comes out the way you want. By carefully inspecting the proof, you can help us assure an accurate, flawless delivery of your print job on the first run. When an artwork proof is selected we check to make sure the artwork file is set up properly for print which includes adding hemming, grommet marks, and cut contour lines (if needed/selected). We are NOT responsible for checking over the quality, information, spelling, grammar, etc. We do recommend if you are concerned with quality to be sure and zoom into the graphics so that way you will also see the banner graphic up close as if it were printed. Very often, a designer will retype information they’ve been supplied when creating a proof. That’s why you need to check every element of the design to make sure it’s correct.

Key areas to check:

- Spelling, grammar and punctuation

- Contact details (phone numbers, names, email addresses, dates, times)

- Pictures and logos (are they sharp enough?)

- Graphic components and images (are all of my images included?)

- Layout (is the information in the correct spot?)

*Note: Colors in your proof may slightly vary from screen to print. (see why)

A revision is considered a change or alteration to an initial or in progress design concept and is typically a change of less than 25% of the design. A revision is meant to be a slight modification or correction in order to progress to the final design.

A new design concept is not considered a revision. A new design concept would be an addition to the project and would need to be estimated separately, in addition to the current project estimate.

Resolution should be set to 300 dpi. Pictures and graphics pulled from the internet are often low resolution, typically 72 dpi or 96 dpi. Avoid these graphics, as they will appear pixilated and blocky when printed.

Also note that you should save all photos in CMYK mode, not RGB mode when possible. Images saved in RGB mode may not print properly. If you are unable to save your image in CYMK mode, please let us know.

Print-ready artwork means that once we receive the file, it can immediately be sent for print. If you have any doubts, checkout our Artwork Specifications. And if you still have questions, contact us.

Your potential customers will judge the authenticity & credibility of your company based off the first impression that they get from your logo. You don't want them to assume that you offer low quality products/services because your logo is low quality.

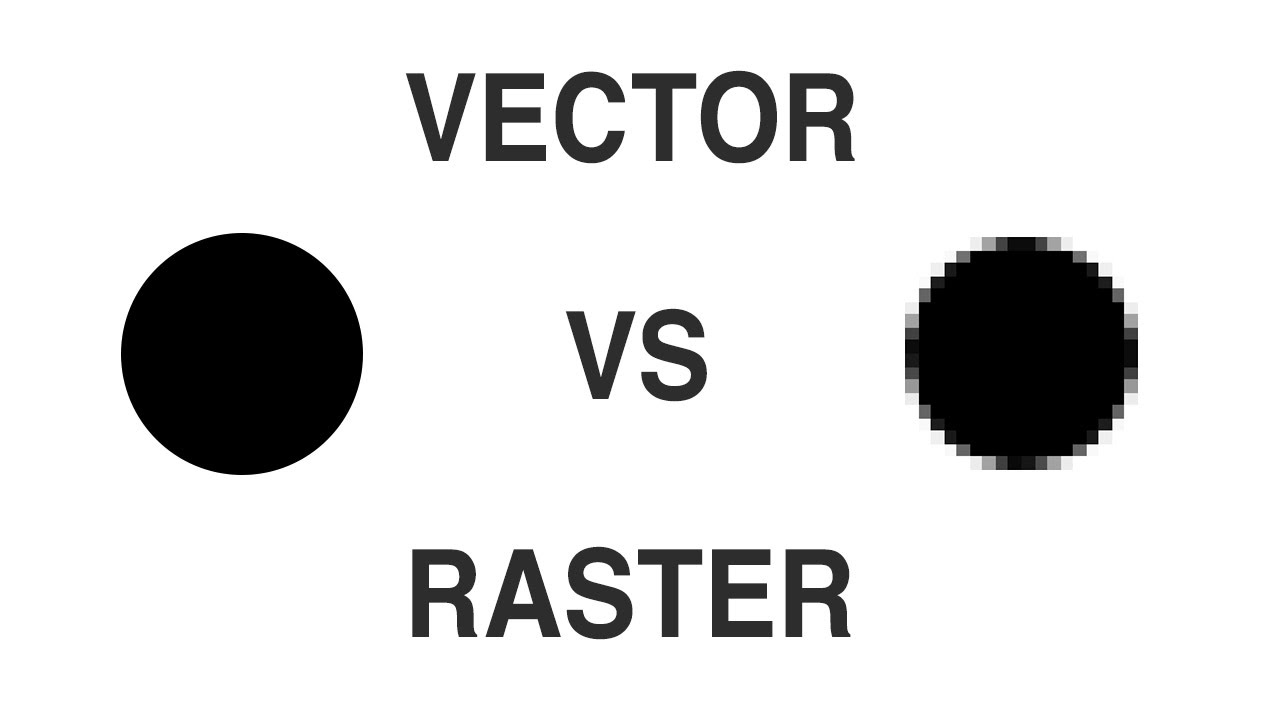

Raster:

A raster image is made of up pixels, each pixel is a different color, arranged to display an image.

Depending on the resolution the image becomes blurry as enlarged.

Examples of Raster files

- PSD

- JPG

- TIFF

- PNG

If submitting these files, please follow the guidelines below:

- 100% scale (full size output) at 100 dpi

- 50% scale at 200 dpi or higher

- 25% scale at 300 dpi or higher

- 10% scale at 600-1200 dpi recommended

Thumbnail sized jpg and gif. files are not at a high enough resolution to be used on large prints like banners.

Vector:

What is neat about vector graphics is unlike JPEGs, GIFs, and BMP images, vector graphics are not made up of a grid of pixels. Instead, vector graphics are comprised of paths, which are defined by a start and end point, along with other points, curves, and angles. Vector based graphics can be scaled to a larger size and not lose any image quality. They can also be scaled small enough to appear on a business card. Typically, if you were to blow up a graphic it will look blocky, or "pixelated." When you blow up a vector graphic, the edges of each object within the graphic stay smooth and clean.

Examples of vector files:

- EPS

- AI

- SVG

Checkout our Artwork Specifications if you have any questions about supplying print-ready artwork to us.

Web FAQ's

We sure do. Learn more about our web services or feel free to fill out a quote form here.

Print FAQ's

In short, printers and monitors produce colors in different ways. Monitors use the RGB (red, green, blue) color model, which usually supports a wider spectrum of colors. Printers use the CMYK (cyan, magenta, yellow, black) color model, which can reproduce most - but not all - of the colors in the RGB color model. Depending on the equipment used, CMYK generally matches 85–90% of the colors in the RGB model. When a color is selected from the RGB model that is out of the range of the CMYK model, the application chooses what it thinks is the closest color that will match.

Print-ready artwork means that once we receive the file, it can immediately be sent for print. If you have any doubts, checkout our Artwork Specifications. And if you still have questions, contact us.

Simple jobs are often completed the same day if the artwork was approved before 12pm, and next day if it was approved after 12pm. Some jobs, however, may take up to seven to ten days to complete depending on their complexity and size. We always strive to provide an accurate estimate of the turnaround time for each job we do. And we’ll always work with you to find ways to complete your project when you need it.

Example of our cut contour types.

Die Cut: The final product will be cut down to the exact shape of the graphic or text. There is no background around the image on the inside or out. This can easily be done with minimal detail and larger sizes.

Cloud Cut: This is in between die-cut and the square cut. Cloud cuts are done when the images or text have very small/thin fonts or details. The image will be printed and cut with a border around the text or image to give a small cushion.

Square Cut: The final product will be printed exactly as it shows, but finished into a square, circle or other solid shapes so it's one piece.

Reseller FAQ

Two Minds knows what it is like to work out of our house. We started this business 8 years ago in the 300sq/ft bedroom above our garage! We outsourced everything in the beginning until we were finally able to buy our first printer. But in that time we learned what made the most valuable partner. We wanted a fast turnaround of our prints, high quality prints that last, and a team that was committed to our businesses success.

If you didn't feel like reading that ^ Here is a quick list! 🙂

Here are the benefits of working with Two Minds Group

- Same day delivery of prints when artwork is approved to print before 12pm, and next day for artwork that is approved to print after 12pm.

- Up to 5x10 seamless prints on rigid substrates

- In-house discounted graphic design services

- Friendly Staff who loves to please it's clients!

- A loud dog that is very friendly!

Unfortunately, we are not able to offer refunds on any printed orders unless there is a problem with the print itself. We send proofs for you to confirm before we start printing to lower the possibility of errors.

It has always been our motto that, "If it doesn't look good, don't send it out to our clients." If your print or experience isn't to your satisfaction, let us know and we will reprint your order or fully credit your account.

We want to partner with your business and help you discover a new source of revenue by becoming a reseller of our digitally printed products.

We require our resellers to provide the following documents:

- Federal tax ID

- Sales and Use Certificate

When ordering all reseller members must provide PRINT READY ARTWORK

LASTLY, You must be in one of the below industries:

- Print Industry

- Sign Shop

- Offset Printers

- Marketing Company

- Our Close Special Friend

- Apparel Companies

- Print Brokers

Think you belong on this list? Send us a message.